“You must love what you do if you want to do it well.”

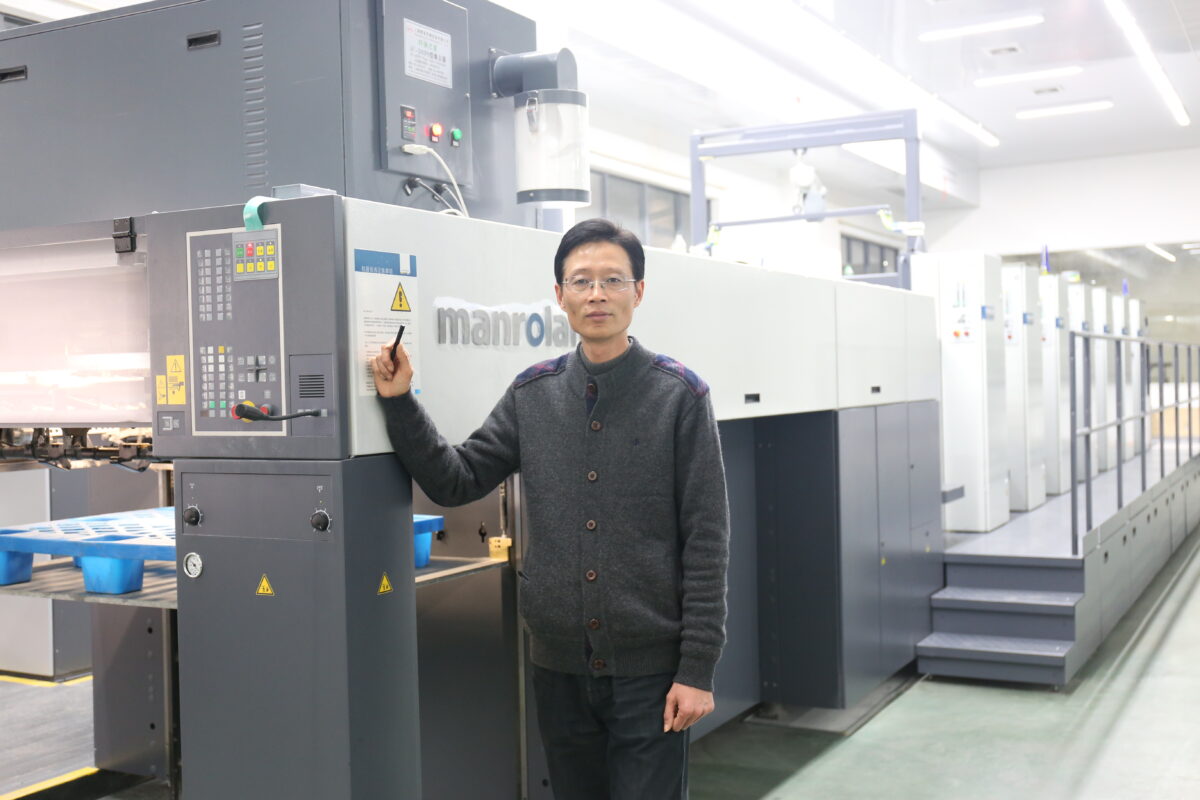

That’s how Mr. Zhang Xiaojiang, Managing Director of Shengzhou Yuchen Packaging & Printing Co. Ltd., summed up his attitude as a professional printer.

It is this kind of attitude that has shaped Shengzhou Yuchen into a successful enterprise.

With an annual production of over RMB100 million, Shengzhou Yuchen offers a wide product range, covering cardboard and packaging for alcohol, cigarettes, cosmetics, color TV and mobile phones.

Operating under the business principle of ‘Integrity, Quality First, Service First, Reasonable Pricing’ the company has continuously improved product quality and production capacity since it was established more than 20 years ago.

Needless to say, its efforts have increased customer satisfaction. And despite various challenges, such as the sluggish growth of the printing industry, overcapacity and shrinking profit margins, Shengzhou Yuchen continues to expand its scale and remains profitable.

Focus on developing its own strength

In 1997, a start-up business in the form of a printing workshop was founded with the help of a modest loan of tens of thousands RMB. The focus was on developing its own strength, so Shengzhou Yuchen strived to improve print quality and production processes. By now, it has grown into a prestigious printing company with an annual production of over RMB100 million.

Over the past two decades, a wealth of experience in management and printing technology has been accumulated, to go with the solid economic and technical foundation that has been laid. It has faced tremendous pressure from the fall-out from the Sino-US trade war and a lot of difficulties in the printing industry, but Shengzhou Yuchen has developed abilities to resist both risk and pressure. It has now acquired a certain maturity, steadily propelling the company forward.

High-end product positioning

Shengzhou Yuchen focuses on high-end products, so it is important to improve the printing process and product quality in order to meet the rigorous requirements of customers. “The whole production process from the printing equipment to the die-cutter in post-printing was totally upgraded,” Mr. Zhang says. “In addition, with the help of green printing supplies and auxiliary materials, advanced printing technology and highly efficient printing service, we have been able to keep our customers happy and so they choose to stay with us. The characteristics of our company’s purchase orders are ‘small and fine’, which determine our place in the market and product positioning. Our development plan is determined by customers needs and order characteristics.”

Choosing the best printing equipment is vital to success Mr. Zhang emphasizes the importance of high-quality printing equipment. “A good press does not only improve product quality, but also brings us more purchase orders and strengthens the customers’ faith in us,” he says. The most important criterion is good quality at reasonable cost.

Since the company’ s initial cooperation with Manroland in 2003, Shengzhou Yuchen print on Manroland presses “At present, we are using a ROLAND 706 LV, which prints up to 17,200 sheets per hour,” Mr. Zhang says. “This significantly increases our productivity and lowers our production costs. It also greatly improves our production capacity, profit margin and competitiveness. We’ re very satisfied with Manroland’ s reliability and stability.”

High-quality printing supplies must be compatible with the machine In addition to excellent printing equipment, the right choice of printing supplies is very important. “Nowadays some printers may not realize that there is some misunderstanding in the selection of printing supplies. Lacking the overall concept, they simply think that the materials used in the market must be a good choice,” says Mr. Zhang. “However, the really good printing supplies should be compatible with the entire machine’s operation.

Printing supplies should not be judged only by part of usage experience or the price. Generally speaking, the cheaper auxiliary materials couldn’ t quite meet the requirements of high-quality printing. The costs of changing spare parts and damages to operation are even immeasurable.

The loss outweighs the gain indeed.” Shengzhou Yuchen have been using printcom® / magicpix® printing supplies and Mr. Zhang explains why. “Firstly, as the professional manufacturer of printing equipment, Manroland understands each part of the press very well and clearly knows which kinds of materials are the most suitable for the printing equipment.

Based on this, Manroland R&D department developed printing supplies that are compatible with the entire machine operation,” Mr. Zhang says. “These printing supplies ensure high-quality printing production apart from improving the efficiency of the machine. They also extend the machine life cycle.” “Secondly, the printcom® / magicpix® washing agents meet safety standards and have environmental protection certifications, including FOGRA. It offers enormous economic advantages, as it has the characteristics of outstanding cleaning power, strong corrosion resistance, low VOC and environmental protection.

What‘s more, printcom® alcohol-free fountain solution is very suitable for the special environment of our production plant. It‘s available in different types, so it meets the various demands of our extensive product range. It’s tailor-made for us.” “Thirdly, Manroland proactively provides us with professional consultancy and the after-sales ProServ360 PERFORMANCE, guiding our operators to ensure the maximum utilization of materials. Our frontline employees all said that these printing supplies are actually very safe to use. The actual operation experience is very good and the equipment compatibility is strong.

The most important part is that it is 10 times more effective. We’ve been able to save on other consumables since we started using it. For example: the W390 wash agent not only has low VOC and low usage, but also is very effective in cleaning. Before using it, we had to use many other auxiliary products, such as color changing paste, deep cleaning paste. But now, using the W390 wash agent alone is enough for cleaning, significantly increasing our productivity.”

Mr. Zhang expressed his optimism about the development prospect of the packaging printing industry. “In the current economic environment, policies of industrial restructuring have been launched, putting great pressure on small enterprises. They face the possibility of elimination from the industry,” he says. “However, our focus on developing our own strength will ensure us that we stand out in the competition. Although for now our profit margin is quite small, we still keep growing steadily. In the future when the balance between supply and demand reaches a reasonable level, profits and purchase orders will also be rationalized. The whole industry will grow in a healthy and positive way.”

Mr. Zhang Xiaojiang, Managing Director of Shengzhou Yuchen Packaging & Printing Co., Ltd, their “can do” attitude has shaped Shengzhou Yuchen into the successful enterprise it is today.

Mr. Zhang Xiaojiang, Managing Director of Shengzhou Yuchen Packaging & Printing Co., Ltd, their “can do” attitude has shaped Shengzhou Yuchen into the successful enterprise it is today.

About Manroland Sheetfed

Manroland Sheetfed GmbH is a leading German producer of sheetfed offset litho printing presses. Founded in 1871, the company is one of the oldest producers of printing presses in the world. Today the company has its own subsidiaries in over 40 countries and is a global watchword for supreme quality and reliability. Manroland Sheetfed GmbH is a wholly owned subsidiary of the privately owned UK engineering group, Langley Holdings plc.